Sika Pro-Tecta

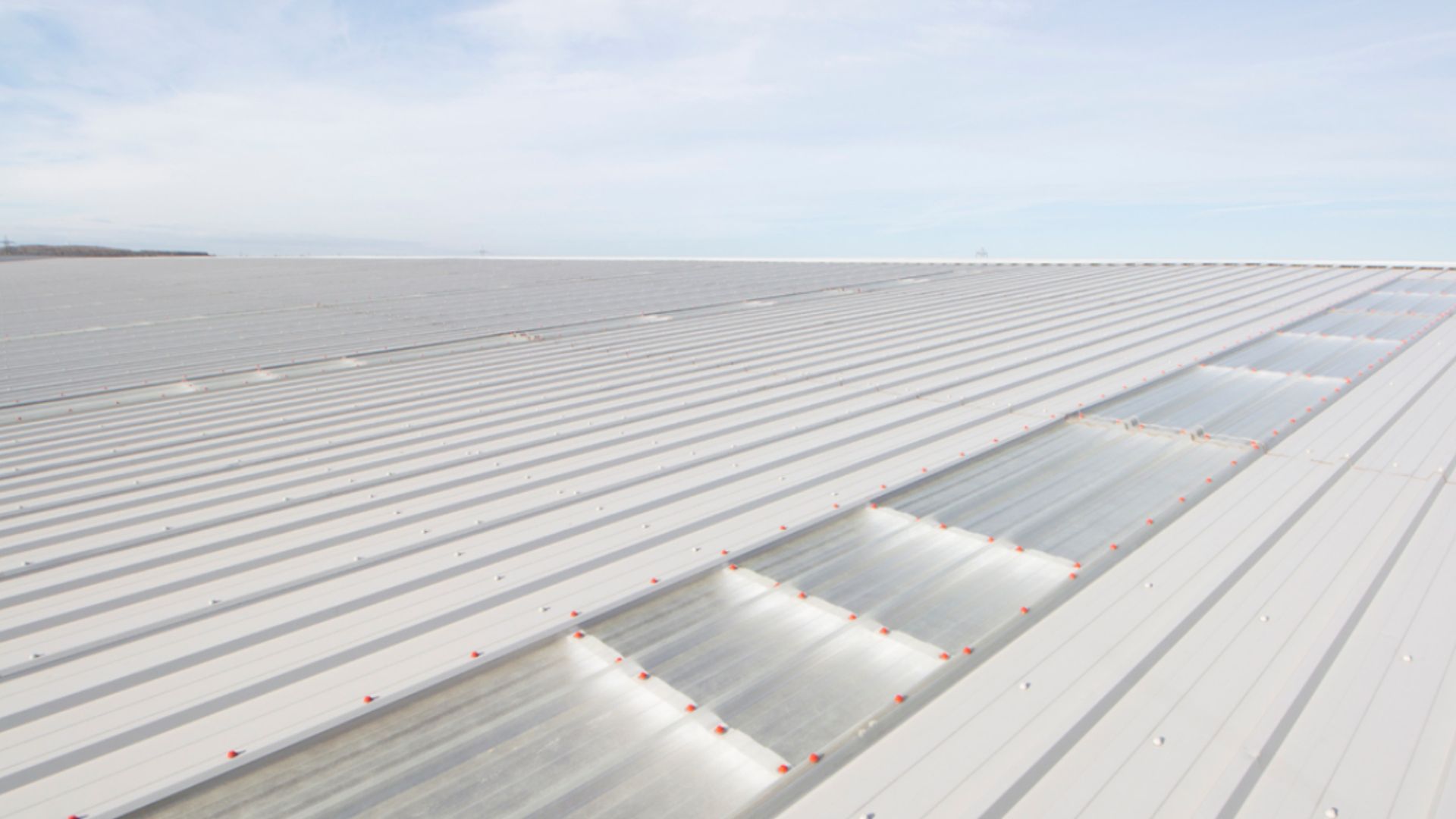

While remedial treatments such as Sika Pro-Tecta CE will be a good choice for early maintenance, it is very often the case that metal roof systems require a more extensive refurbishment solution, particularly where sheets are damaged or leaking. Sika Pro-Tecta WP is our new and enhanced waterproofing system, which has been engineered around our two flagship polyurethane membranes.